<prev

Roll Bar

Main Pads Fitment Weld

Paint Install next>

Weld

Warning! The coatings used on car bodies make toxic vapors when welded!

If welding the car you need to grind away the paint and coatings and

use proper ventilation. In my case, since my cage is bolt-in, I was

welding only to the clean steel of the roll bar tubes and pads, and

never directly to the car metalwork.

I used a TIG welder to weld the roll bar. This was nice, as TIG makes

little smoke or sparks, so I could weld inside the car without ruining

the interior. I just tack welded everything inside the car, took the

assembly outside the car to fnish weld everything, and then put it back

into the car for bolting. I was very happy when the roll bar fit within

about 1 mm. I had been worried the welding might warp things, but in

this case I got lucky.

To stay in stock class in SCCA autocross, I have to have a bolt-in roll

bar. After having done this, I think it might actually be easier to

weld in a roll bar. You don't have to put pads on the underside; you

don't have to mess with the bolts; and you don't have to take the cage

out for welding it (although that might make things easier). Even

though this cage is bolt-in, it was enough work to bolt it into the car

that I plan to never remove it.

I couldn't get the ground clamp to grab onto the roll bar directly, so

I clamped on vice grips and grounded to that instead.

This just shows tack welding inside the car. Damp towels were used to

protect nearby wiring and rubber. The triangle magnet is helping hold

the pad in place. Warning, if you get a magnet too close to where you

are welding, the magnetic field will turn the arc and make it

sputter.

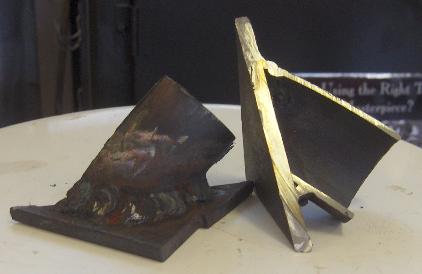

Here are pictures of the welds of the tubes to the pads. It was hard to

weld into the narrow angle part, so next time I do this I'll have the

tube bent so it meets the pad at a 90 degree angle. Rules say you need

to weld all the way around the tube and have no undercut. Note the

right side rear fenderwell pad is flat, but the left side is curved.

Hats off the the world's great welders, I'm still a beginner and have

newfound respect for the great looking welds you see on modern

motorcycles and bicycles.

Here are the welds where the stays meet the main hoop.

I actually did these first, but since they are less exciting I put them

at the end. These are some test welds I did for practice before

tackling the real thing. I cut some of the welds to make sure I had

thorough fusion. I also put them in a vice and tried to break the welds

by hammering -- all the welds held. Sometimes little test welds like

this are called "welder's coupons" and can be used to prove the welder

had the skill needed to do the job safely.

Keywords: Camaro, Firebird, LT1, LS1, autocross, road racing, SCCA,

NHRA, drag racing, safety, roll bar, welding, racing rules

<prev

Roll Bar

Main Pads Fitment Weld

Paint Install next>